If you package food, beverage, or oil into cans, it is crucial to create an airtight or hermetic seal with your can seam to protect your product. Follow-up and inspection of those seams is just as important to ensure your product maintains its quality and to keep unwanted substances from passing in or out.

Let’s break down the basics below.

What is a Hermetic Can seam?

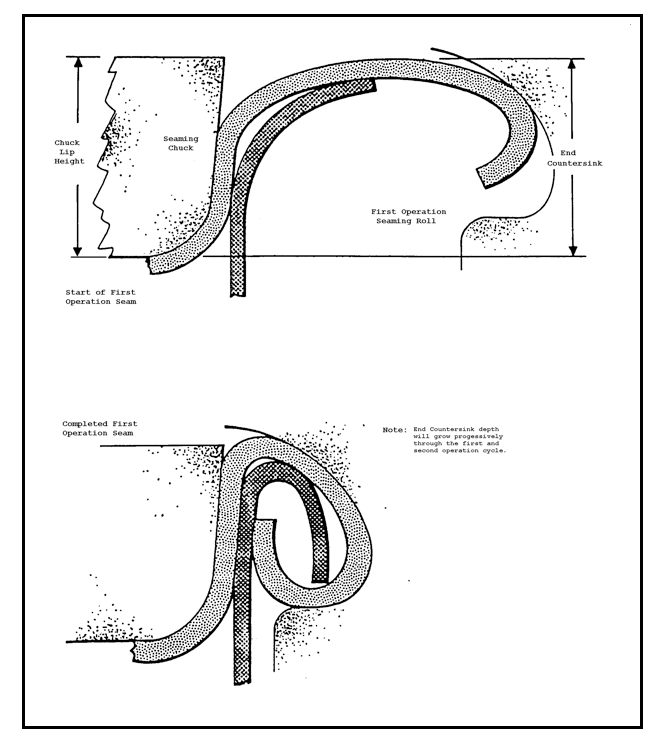

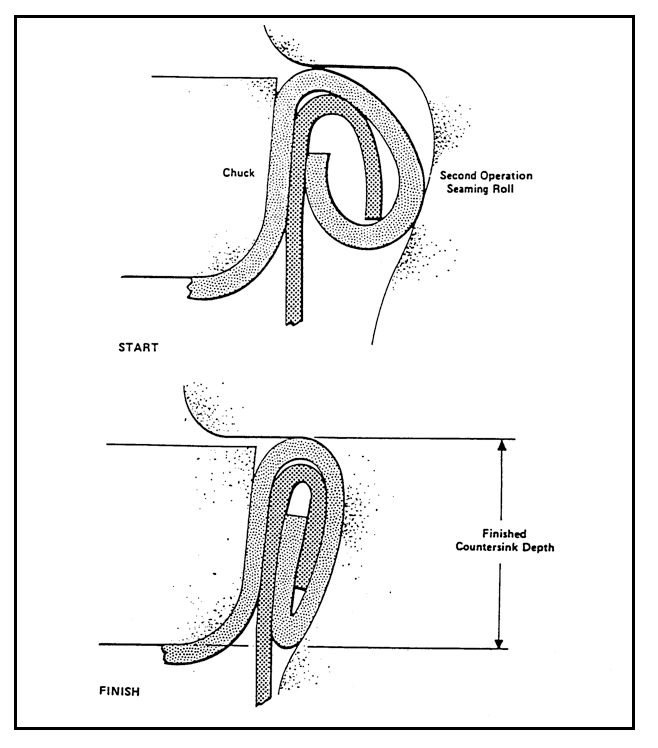

A hermetic can seam, or double seam, is formed by interlocking the edges of the can end and the can body. This is done by a can seamer through a two-stage operation. The first operation involves curling the body of the can into the can end to create a cover hook. The second operation tightens and flattens the seam together to create the double seam. A sealing compound is also applied to keep the seam together and maintain its airtight seal. This process creates the airtight seals needed to contain and preserve the product inside the can.

First Operation

Second Operation

The Can Seam Inspection Process

Can Seam Inspection is the formal procedure for inspecting the double seam to ensure canned products are properly sealed to preserve the product’s quality and protect the product during distribution. This process involves measuring external and internal seam dimensions as well as checking for any possible seam defects.

Specifically, the inspection aims to verify four essential requirements of a quality double seam:

1. Correct Tightness: The seam needs to be sufficiently tight to allow the sealing compound to hold under compression.

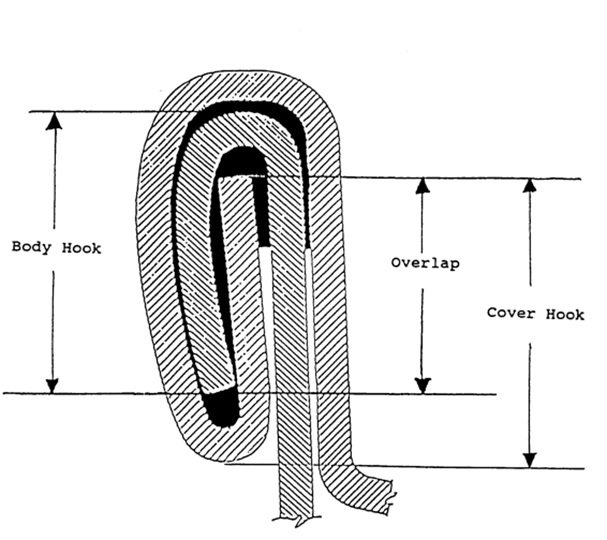

2. Correct Body Hook & Cover Hook Length: The length of the cover hook and the body hook are measured to confirm they are within proper tolerances.

3. Correct Overlap: There must be sufficient overlap of the cover and body hooks to ensure an airtight seam.

4. Other Critical Defects: Seam needs to be free of distortions such as false seams, vees, sprung seams, or seam bumps.

To evaluate these four requirements, several measurements need to be taken:

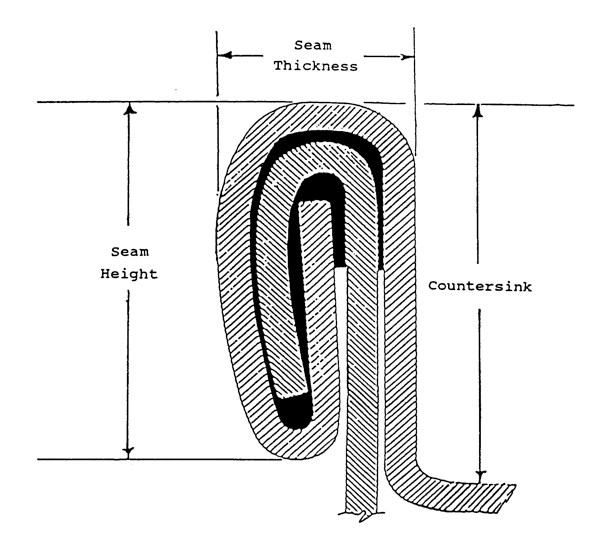

• Countersink Depth

• Seam Thickness

• Body Hook

• Cover Hook

• Overlap

• Seam Height

• % Overlap

• % Body Hook Butting

• Seam Tightness

External Double Seam Dimensions

Internal Double Seam Dimensions

These measurements need to be compared to the can manufacturer’s double seam specifications to ensure they fit within safety parameters. If they do, you can be assured that your seams will perform well during the packaging and distribution of your products. If they don’t, you now have the data needed to inspect and adjust your can seamer appropriately.

Tools for Conducting Can Seam Inspection

Conducting can seam inspections requires specific tools to collect critical measurements during the inspection.

A countersink gauge measures the countersink depth.

Manual tools such as a micrometer and calipers measure seam thickness and seam height.

Seam saws make vertical cuts through the double seam in order to view the internal characteristics of the seam.

Video imaging systems show the external and internal double seam measurements such as seam height, seam thickness, body hook, overlap, and cover hook.

Seam strippers or handheld manual tools “tear down” a can (remove the cover hook) to evaluate seam tightness and seam defects. You can learn more about the step-by-step process of a manual teardown here. Seam Strippers perform this task more safely and efficiently.

In Conclusion

Hermetic double seams are formed when the can body and the can lid are folded together properly to seal the can and prevent leaks and contamination. The critical step of can seam inspection involves taking specific measurements to ensure double seam quality. Both manual and automated tools can be used to inspect can seams.

OneVision specializes in can seam inspection equipment and delivers comprehensive, affordable solutions that help businesses ensure shelf stable products and meet regulatory requirements.